Daily Driver Rollbar Project

#1

Mach 1 Member

Thread Starter

Daily Driver Rollbar Project

With time off from work, I've had a chance to write up my rollbar project for my ’06 Mustang GT street car/track day car. It’s been an ongoing project that I started last winter and finally had a chance to finish up last month. It isn’t perfect , but I’m fairly happy with how it turned out. Needless to say, I can’t thank Alan Blaine and others enough for their shared experience in this thread from cornercarvers.com (http://www.corner-carvers.com/forums...ad.php?t=27556).

My main criteria was to have something that was (1) at least as safe, or preferably safer than an Autopower (i.e. no floorpan punch-through); and (2) something that could be *easily* installed/removed for track events, since my kids still love going for rides in the Mustang. This ruled out all the bolt-in designs out there I could find.

My idea for the main hoop mounting came from the Griggs and Maximum Motorsports designs. They validated in my mind that the bulkhead was a much stronger point to mount the hoop than the floorpan and that remaking the factory bulkhead gusset was the way to go. The only hitch is that neither design is easily removed/installed (i.e. the night before a track day in under 30 minutes).

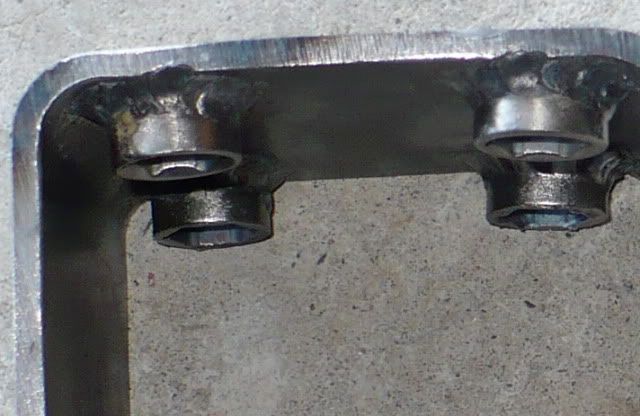

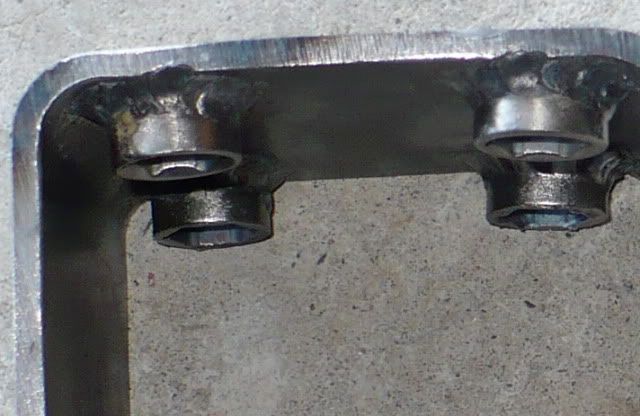

So what I did was basically remake the factory bulkhead gusset using 1/8” plate and a section of 4”x4” x 3/16” square tube. The 4” height off the bulkhead was perfect. I also welded in 4 captive nuts before closing off the end with a piece of 3/16”. Yes, probably way overkill using the section of socket (later capped off with a washer), but in my prior experience on my old Jeep with spot welded nuts they always seemed to fail:

Here it is mounted:

And with the rollbar on it during construction while the interior was still apart to give a better idea of how it sits:

Once the interior is back together, the only hint that there is a provision for a rollbar is a cutout on either side of the back seat, which I trimmed with some edging from McMaster-Carr.

That picture reminds me I still have to touch it up with a fresh coat of Rustoleum black epoxy paint.

The other area where I wrestled with the design to keep it easily installed/removed was the rear stays. The Autopower slip fit design is something I contemplated, but I wanted at least one rear diagonal which would have made this *much* more difficult to keep aligned, etc… during welding—i.e. perfectly parallel is something I don’t think I could have managed.

I settled on the 4-bolt flange design after seeing a nice S197 on the NASA forums using this design for a petty bar. For the actual rear stays I used 1.75 x 0.120 DOM, and then 1.5 x 0.090 DOM for the diagonals. The mounting plates are 3/16” drilled for 3/8” bolts. The gussets are 1/8” and placement still allows easy access to the bolts.

And again for the mounting box on the floor, I used 3/16” plate and captive nuts. I also threw in a crossbar, since I had leftover 1.5” tubing.

For the main hoop, since I don’t have a bender and wasn’t going to buy one for a one-off project, I sent measurements to a guy down by VIR. 4 days later I had my hoop. Nothing too special here—just 1.75 x 0.120 DOM tubing for the hoop, diagonal and harness bars. I landed the diagonal over my head in seating position, and intersected the rear stay with the same node. Thanks again to Alan Blaine at Blaine-Fabrication for the “steel teepee” visual from way back.

I finished it up with a few coats of Rustoleum appliance epoxy in silver. With it complete, installation is basically:

1) Fold down rear seats

2) Bolt the rear section in place (8 bolts total)

3) Place the main hoop on their landing pads on the bulkhead

4) Bolt the rear section to the main hoop (8 nuts/bolts)

5) Bolt the main hoop to the landing pad (8 bolts)

6) Bolt seats to seat back braces

It’s a lot of bolts to fasten, but I timed myself and can install the entire thing in less than 20 minutes.

Things I would have done differently are (I’m sure there are more):

Like I said, not perfect, but I’m reasonably happy with it. I may add some seatbelt B-pillar mount provisions later this year if I can find time and I'm sure there are plenty of other improvements that could be done...

My main criteria was to have something that was (1) at least as safe, or preferably safer than an Autopower (i.e. no floorpan punch-through); and (2) something that could be *easily* installed/removed for track events, since my kids still love going for rides in the Mustang. This ruled out all the bolt-in designs out there I could find.

My idea for the main hoop mounting came from the Griggs and Maximum Motorsports designs. They validated in my mind that the bulkhead was a much stronger point to mount the hoop than the floorpan and that remaking the factory bulkhead gusset was the way to go. The only hitch is that neither design is easily removed/installed (i.e. the night before a track day in under 30 minutes).

So what I did was basically remake the factory bulkhead gusset using 1/8” plate and a section of 4”x4” x 3/16” square tube. The 4” height off the bulkhead was perfect. I also welded in 4 captive nuts before closing off the end with a piece of 3/16”. Yes, probably way overkill using the section of socket (later capped off with a washer), but in my prior experience on my old Jeep with spot welded nuts they always seemed to fail:

Here it is mounted:

And with the rollbar on it during construction while the interior was still apart to give a better idea of how it sits:

Once the interior is back together, the only hint that there is a provision for a rollbar is a cutout on either side of the back seat, which I trimmed with some edging from McMaster-Carr.

That picture reminds me I still have to touch it up with a fresh coat of Rustoleum black epoxy paint.

The other area where I wrestled with the design to keep it easily installed/removed was the rear stays. The Autopower slip fit design is something I contemplated, but I wanted at least one rear diagonal which would have made this *much* more difficult to keep aligned, etc… during welding—i.e. perfectly parallel is something I don’t think I could have managed.

I settled on the 4-bolt flange design after seeing a nice S197 on the NASA forums using this design for a petty bar. For the actual rear stays I used 1.75 x 0.120 DOM, and then 1.5 x 0.090 DOM for the diagonals. The mounting plates are 3/16” drilled for 3/8” bolts. The gussets are 1/8” and placement still allows easy access to the bolts.

And again for the mounting box on the floor, I used 3/16” plate and captive nuts. I also threw in a crossbar, since I had leftover 1.5” tubing.

For the main hoop, since I don’t have a bender and wasn’t going to buy one for a one-off project, I sent measurements to a guy down by VIR. 4 days later I had my hoop. Nothing too special here—just 1.75 x 0.120 DOM tubing for the hoop, diagonal and harness bars. I landed the diagonal over my head in seating position, and intersected the rear stay with the same node. Thanks again to Alan Blaine at Blaine-Fabrication for the “steel teepee” visual from way back.

I finished it up with a few coats of Rustoleum appliance epoxy in silver. With it complete, installation is basically:

1) Fold down rear seats

2) Bolt the rear section in place (8 bolts total)

3) Place the main hoop on their landing pads on the bulkhead

4) Bolt the rear section to the main hoop (8 nuts/bolts)

5) Bolt the main hoop to the landing pad (8 bolts)

6) Bolt seats to seat back braces

It’s a lot of bolts to fasten, but I timed myself and can install the entire thing in less than 20 minutes.

Things I would have done differently are (I’m sure there are more):

- I would have landed the main diagonal about 2 inches further outboard, which then would have landed each rear stay about 2 inches further outboard.

- I also would have used a larger mounting flange/box to give more wiggle room for mounting the tubes after they shifted during welding.

- I would have built the rear stay mounting boxes an inch or two lower. I was overly concerned with having enough height to allow easy wrench access, but overdid it a bit.

Like I said, not perfect, but I’m reasonably happy with it. I may add some seatbelt B-pillar mount provisions later this year if I can find time and I'm sure there are plenty of other improvements that could be done...

#2

Nice, I've been thinking about a similar thing for my convertible. I am now quick enough (even with a V6 - quicker than 13.49) that under NHRA rules I should have a 4 point roll bar. My dilemma has been the same as yours, something that I can remove so my granddaughter can still ride in the back but that I can quickly install on Friday night for the track on the weekend.

#4

Mach 1 Member

Thread Starter

main hoop was $90 plus shipping

24' of 1.75" tubing was ~ $150 if I remember right

15' of 1.5" tubing was ~ $75

Misc. 3/16" and 1/8" plate was another ~ $100

2' Section of 4"x4"x3/16" square tube was ~ $25

Grade 8 3/8" nuts and bolts ~ $20

Let's call it about $500 for everything including paint. I have a lot of leftover steel for other projects, too.

And of course, my labor is free. Seriously, though, I figure I have about 50 hours into the entire project. Not something I want to do again any time soon, but the planning and building was pretty fun.

Seriously, though, I figure I have about 50 hours into the entire project. Not something I want to do again any time soon, but the planning and building was pretty fun.

24' of 1.75" tubing was ~ $150 if I remember right

15' of 1.5" tubing was ~ $75

Misc. 3/16" and 1/8" plate was another ~ $100

2' Section of 4"x4"x3/16" square tube was ~ $25

Grade 8 3/8" nuts and bolts ~ $20

Let's call it about $500 for everything including paint. I have a lot of leftover steel for other projects, too.

And of course, my labor is free.

Seriously, though, I figure I have about 50 hours into the entire project. Not something I want to do again any time soon, but the planning and building was pretty fun.

Seriously, though, I figure I have about 50 hours into the entire project. Not something I want to do again any time soon, but the planning and building was pretty fun.

#5

Member

Join Date: January 7, 2009

Location: The OC, CA

Posts: 27

Likes: 0

Received 0 Likes

on

0 Posts

it's funny

once i get the v8 in, this was going to be my next project for my winter break. pretty much the same thing - a bolt-in roll bar that is safer than the autopower but still removable (or maybe just partially removable, like for access to the rear seats or something) for daily driving.

good job!

once i get the v8 in, this was going to be my next project for my winter break. pretty much the same thing - a bolt-in roll bar that is safer than the autopower but still removable (or maybe just partially removable, like for access to the rear seats or something) for daily driving.

good job!

#7

Mach 1 Member

Thread Starter

it's funny

once i get the v8 in, this was going to be my next project for my winter break. pretty much the same thing - a bolt-in roll bar that is safer than the autopower but still removable (or maybe just partially removable, like for access to the rear seats or something) for daily driving.

good job!

once i get the v8 in, this was going to be my next project for my winter break. pretty much the same thing - a bolt-in roll bar that is safer than the autopower but still removable (or maybe just partially removable, like for access to the rear seats or something) for daily driving.

good job!

Took it out this past Monday to Buttonwillow. Had a blast and it is amazing how being tightly retained adds to the overall relaxation level on the track.

#8

Bullitt Member

Nice job. Very well thought out.

I too have mine welded to the bulk head and not the floor. I am wondering now if I need to reinforce it a little better. Hmmm

I too have mine welded to the bulk head and not the floor. I am wondering now if I need to reinforce it a little better. Hmmm

#9

Mach 1 Member

Thread Starter

Very nice! Nothing beats the look (or strength) of some nice TIG welding. One day, one day...

I've never seen a diagonal mounted that way, but have to say that is a **** clever way of getting more weld contact area. Why the split diagonal instead of harness bar? Every fabricator has a preference on this it seems.

I'm still up in the air about padding--when strapped in no matter how hard I try, I can't even touch any part of the bar. I guess in a bad enough impact the seat could flex or break, though, so I'll probably end up strapping on some high density stuff around the head area.

I've never seen a diagonal mounted that way, but have to say that is a **** clever way of getting more weld contact area. Why the split diagonal instead of harness bar? Every fabricator has a preference on this it seems.

I'm still up in the air about padding--when strapped in no matter how hard I try, I can't even touch any part of the bar. I guess in a bad enough impact the seat could flex or break, though, so I'll probably end up strapping on some high density stuff around the head area.

Last edited by Import-Slaya; 12/26/09 at 12:50 PM.

#10

Bullitt Member

Very nice! Nothing beats the look (or strength) of some nice TIG welding. One day, one day...

I've never seen a diagonal mounted that way, but have to say that is a **** clever way of getting more weld contact area. Why the split diagonal instead of harness bar? Every fabricator has a preference on this it seems.

I'm still up in the air about padding--when strapped in no matter how hard I try, I can't even touch any part of the bar. I guess in a bad enough impact the seat could flex or break, though, so I'll probably end up strapping on some high density stuff around the head area.

I've never seen a diagonal mounted that way, but have to say that is a **** clever way of getting more weld contact area. Why the split diagonal instead of harness bar? Every fabricator has a preference on this it seems.

I'm still up in the air about padding--when strapped in no matter how hard I try, I can't even touch any part of the bar. I guess in a bad enough impact the seat could flex or break, though, so I'll probably end up strapping on some high density stuff around the head area.

I still haven't put any padding in. The piece that is in the picture is so that it doesn't damage factory passenger seat.

I had this done at http://www.racecarbuilders.com/ . Anthony does great work. This is the third car I have had done with him.

#11

V6 Member

Join Date: September 29, 2008

Location: Denver, Co.

Posts: 63

Likes: 0

Received 0 Likes

on

0 Posts

ummmm, do all rear seats fold down? sorry for the stupid question, but my 2001 the rear seats folded down, but I can't get them to fold on my 2008, am I missing a catch release somewhere?

OK, I found the loop to pull, it was hiding behind the seatbelt, duh.

OK, I found the loop to pull, it was hiding behind the seatbelt, duh.

Last edited by Suntzu; 1/6/10 at 10:30 AM.

#12

Wow, nice stuff in here! You are one crafty guy!

Thread

Thread Starter

Forum

Replies

Last Post

tj@steeda

2015 - 2023 MUSTANG

0

9/24/15 08:15 PM

When is the maiden voyage planned for the track?!

When is the maiden voyage planned for the track?!