Brake Tech: Brake Rotor Types

The disc, or brake rotor, comes in different types and flavors. In this Brake Tech article we’ll show you the major types that you’ll see most in OEM and aftermarket disc brake systems.

Up first is the solid disc brake, a single piece of metal that is usually constructed of cast iron in OEM applications. There are two-piece solid disc brakes as well, but those are usually found in aftermarket applications. Being a single, solid piece, it can be very easy to see when it is ready to be replaced as the surface begins to wear out. However, while being a single piece and simple makes it very inexpensive, it is easy to overheat in high-performance applications.

Next is the vented disc brake rotor. You can tell you have a vented disc by simply looking at the rotor head-on. You’ll see that the front and rear surfaces of the rotor are connected by little slats. Those slats are actually vanes that allow air to flow through to cool the rotor . Most front and aftermarket rotors will be of a vented type. They are more expensive to produce, but the cooling generated by the vanes will more than make up for this in high-performance applications.

In very-high-performance and aftermarket performance brake rotors, you’ll notice that the surface isn’t always smooth. The surface will either have holes or slots cut into it. These slots and holes are designed to remove the gasses that build up from the heating of the adhesive that bonds the brake friction material to its packing plate. Cross-drilled rotors will use the flow of air in the rotor vanes to evacuate those gasses; however, it comes at the cost of rotor surface strength and longevity.

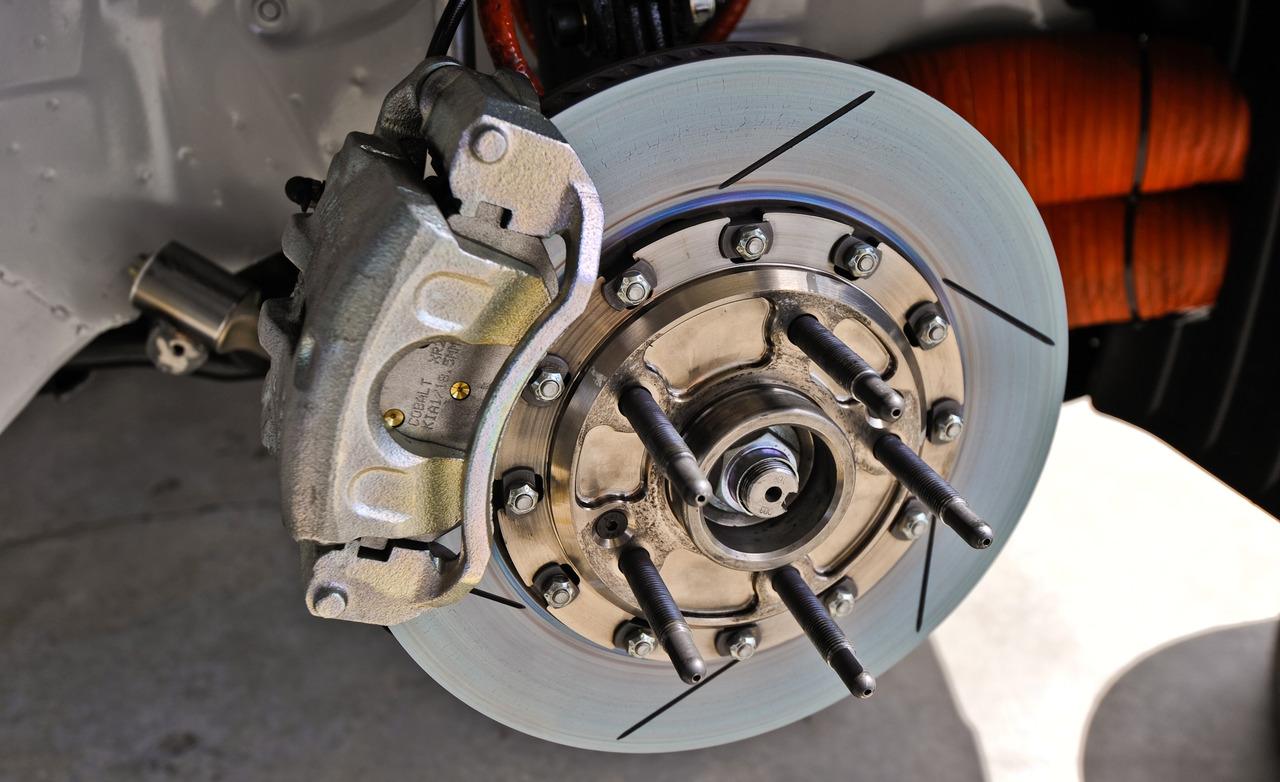

Slotted rotors, on the other hand, will not only remove those gasses, but also retain the strength and help remove some of the non-burnable debris from the friction material. Both cross-drilled and slotted rotors are directional, so be sure to confirm with your rotor manufacturer on the correct direction before installing a set. You’ll also see cross-drilled and slotted rotors in some applications. Consider them a “best of both worlds” solution.

Finally, you’ll see multi-piece rotors that have a rotor and brake hat as two separate pieces that are held together by bolts and locking nuts. These are usually seen on very high-performance OEM and aftermarket applications. This can save some money in the long run as you’ll only have to replace the rotor surface when it wears out, or if you want to increase the size of the rotor face. However, the initial purchase can be fairly expensive.