Potential 66

#1

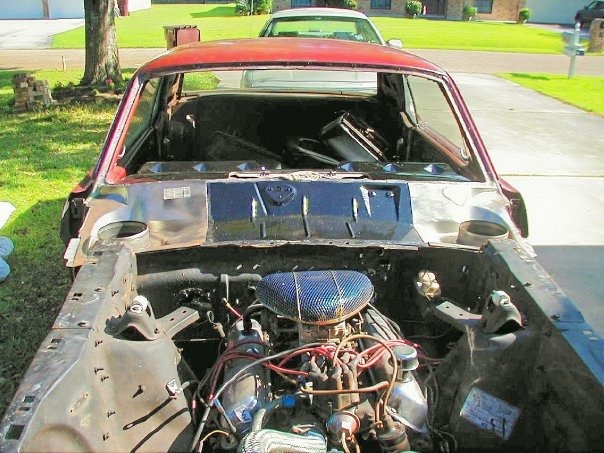

Hello all, new to this forum but not others. I'm 23 years old, ive been working as a plumbers helper for the past 6 years while going to school at night. I'm happy to say I'll be graduating in May with an associates degree in applied sciences and a technical degree in instrumentation. I'm going to try to get on at one of the many chemical or petroleum plants down here in southeast Louisiana. I have a guy I know that just messaged me saying he's not gonna have to money to restore his 66 coupe and wanted to know if I'm interested. So obviously I told him yes but I wouldn't have a place to store it for a few months. I will try to upload a picture of it. he said he would like to get around $1500 for it but I told him we would talk once I checked it out. he said it has a clean title and the rust he found is on the center console area of the hump thing and the battery area under the hood. it has the Code C 289 cubic inch V8 with 2 bbl carb, 3 speed "cruise-o-matic" automatic transmission. I understand it will be a lot of headache to get restored but I've always wanted a 66 mustang and a coupe is a plus! I have a jeep tj so if any of you have jeeps you know if you can put up with a jeep you can put up with just about anything! lol that's a little bit about me an the potential car I might be buying.

I have two main questions

1) if the frame and rest of the body are in good shape with no rust is $1500 a good price? I would probably give him $1000 cash

2) restoration cost

im looking at the picture below and the little info I have on it what would be a really rough estimate of a well done resorption if everything went ok. for you other 66 coupe guys how much has your restoration costed you so far?

just trying to see what I'm getting myself into.

I have two main questions

1) if the frame and rest of the body are in good shape with no rust is $1500 a good price? I would probably give him $1000 cash

2) restoration cost

im looking at the picture below and the little info I have on it what would be a really rough estimate of a well done resorption if everything went ok. for you other 66 coupe guys how much has your restoration costed you so far?

just trying to see what I'm getting myself into.

Last edited by raif281; 3/14/16 at 07:38 PM.

#2

If the frame is good and the body panels are good, the rest is easily dealt with.

Problem areas for rust, in addition to the battery area, are the door panel insides near the front, quarter panels at the bottom, both sides of the wheel well, and the air vents under the cowling. Sometimes people screw up the cowling vents trying to stop the leaks, so that could be damaged as well.

If the hump is rusted, I'd be suspect of the floorpan in general. That's... weird. And it would be a huge red flag for the work that's about to begin to burn a hole in your wallet, watches, and clocks.

Example for grins: If the doors are rusted out, you can get new ones, and they're 'only' about 300 bucks. As to how well they fit this car... But these, and just about every piece of sheet metal for the car, are available. Just how much you wanna spend on it.

But these, and just about every piece of sheet metal for the car, are available. Just how much you wanna spend on it.

You might wanna put your eyes on it. The frame and vin plate are the keys to having a '66 Mustang, though, because pretty near *everything* is otherwise available, for fixing or modding. That's where the scary numbers come in.

You probably need to put your eyes/hands on it yourself to make your own decision. But 1000-1500 for a straight-enough body and good frame? It sounds like a pretty good basis for a project... Especially if you get it all for $1000. You can probably sell the engine/trans for a lot of that back, I'd guess.

Oh, and revisit this thread for my ideas for ya. Not that you'll do it, but... still.

https://themustangsource.com/forums/...1/#post6971934

Engine/tranny/axle/suspension I leave up to you... provided you get this project.

As far as restoration cost? More up to you and how far you wanna go. And how much you can do yourself vs have to outsource.

Back in '91-92 I spent something like 10 grand for my Muskrat resto, including the car. I did a ton of work myself. Seats, body work, interior restoration, wiring. I outsourced the I6 motor and trans, swapped out a good axle, acquired new wheels and tires, did all the suspension work myself... It was about 75% me and 25% others here and there.

And I sold her. Stupid.

Today, that'd be gettin' up to about $17-20K in costs total.

And I was doing it as cheap as possible, because I didn't have a ton of cash at any given time. Took me 2 years in the backyard too. Worth it, if only for the experience, but also the pride in saying "I did (most) of that!" I hate that I let her go though. Won't be happening with Awesome, I can tell you that.

Dunno if I helped or not, but there's my take. I say get it, as long as the rust can be accounted for and accepted as being fixable. And it's got a good vin plate.

Problem areas for rust, in addition to the battery area, are the door panel insides near the front, quarter panels at the bottom, both sides of the wheel well, and the air vents under the cowling. Sometimes people screw up the cowling vents trying to stop the leaks, so that could be damaged as well.

If the hump is rusted, I'd be suspect of the floorpan in general. That's... weird. And it would be a huge red flag for the work that's about to begin to burn a hole in your wallet, watches, and clocks.

Example for grins: If the doors are rusted out, you can get new ones, and they're 'only' about 300 bucks. As to how well they fit this car...

But these, and just about every piece of sheet metal for the car, are available. Just how much you wanna spend on it.

But these, and just about every piece of sheet metal for the car, are available. Just how much you wanna spend on it.You might wanna put your eyes on it. The frame and vin plate are the keys to having a '66 Mustang, though, because pretty near *everything* is otherwise available, for fixing or modding. That's where the scary numbers come in.

You probably need to put your eyes/hands on it yourself to make your own decision. But 1000-1500 for a straight-enough body and good frame? It sounds like a pretty good basis for a project... Especially if you get it all for $1000. You can probably sell the engine/trans for a lot of that back, I'd guess.

Oh, and revisit this thread for my ideas for ya. Not that you'll do it, but... still.

https://themustangsource.com/forums/...1/#post6971934

Engine/tranny/axle/suspension I leave up to you... provided you get this project.

As far as restoration cost? More up to you and how far you wanna go. And how much you can do yourself vs have to outsource.

Back in '91-92 I spent something like 10 grand for my Muskrat resto, including the car. I did a ton of work myself. Seats, body work, interior restoration, wiring. I outsourced the I6 motor and trans, swapped out a good axle, acquired new wheels and tires, did all the suspension work myself... It was about 75% me and 25% others here and there.

And I sold her. Stupid.

Today, that'd be gettin' up to about $17-20K in costs total.

And I was doing it as cheap as possible, because I didn't have a ton of cash at any given time. Took me 2 years in the backyard too. Worth it, if only for the experience, but also the pride in saying "I did (most) of that!" I hate that I let her go though. Won't be happening with Awesome, I can tell you that.

Dunno if I helped or not, but there's my take. I say get it, as long as the rust can be accounted for and accepted as being fixable. And it's got a good vin plate.

Last edited by houtex; 3/14/16 at 09:22 PM.

#3

If the frame is good and the body panels are good, the rest is easily dealt with. Problem areas for rust, in addition to the battery area, are the door panel insides near the front, quarter panels at the bottom, both sides of the wheel well, and the air vents under the cowling. Sometimes people screw up the cowling vents trying to stop the leaks, so that could be damaged as well. If the hump is rusted, I'd be suspect of the floorpan in general. That's... weird. And it would be a huge red flag for the work that's about to begin to burn a hole in your wallet, watches, and clocks. Example for grins: If the doors are rusted out, you can get new ones, and they're 'only' about 300 bucks. As to how well they fit this car...  But these, and just about every piece of sheet metal for the car, are available. Just how much you wanna spend on it. You might wanna put your eyes on it. The frame and vin plate are the keys to having a '66 Mustang, though, because pretty near *everything* is otherwise available, for fixing or modding. That's where the scary numbers come in. You probably need to put your eyes/hands on it yourself to make your own decision. But 1000-1500 for a straight-enough body and good frame? It sounds like a pretty good basis for a project... Especially if you get it all for $1000. You can probably sell the engine/trans for a lot of that back, I'd guess. Oh, and revisit this thread for my ideas for ya. Not that you'll do it, but... still.

But these, and just about every piece of sheet metal for the car, are available. Just how much you wanna spend on it. You might wanna put your eyes on it. The frame and vin plate are the keys to having a '66 Mustang, though, because pretty near *everything* is otherwise available, for fixing or modding. That's where the scary numbers come in. You probably need to put your eyes/hands on it yourself to make your own decision. But 1000-1500 for a straight-enough body and good frame? It sounds like a pretty good basis for a project... Especially if you get it all for $1000. You can probably sell the engine/trans for a lot of that back, I'd guess. Oh, and revisit this thread for my ideas for ya. Not that you'll do it, but... still.  https://themustangsource.com/forums/...1/#post6971934 Engine/tranny/axle/suspension I leave up to you... provided you get this project.

https://themustangsource.com/forums/...1/#post6971934 Engine/tranny/axle/suspension I leave up to you... provided you get this project.  As far as restoration cost? More up to you and how far you wanna go. And how much you can do yourself vs have to outsource. Back in '91-92 I spent something like 10 grand for my Muskrat resto, including the car. I did a ton of work myself. Seats, body work, interior restoration, wiring. I outsourced the I6 motor and trans, swapped out a good axle, acquired new wheels and tires, did all the suspension work myself... It was about 75% me and 25% others here and there. And I sold her. Stupid. Today, that'd be gettin' up to about $17-20K in costs total. And I was doing it as cheap as possible, because I didn't have a ton of cash at any given time. Took me 2 years in the backyard too. Worth it, if only for the experience, but also the pride in saying "I did (most) of that!" I hate that I let her go though. Won't be happening with Awesome, I can tell you that. Dunno if I helped or not, but there's my take. I say get it, as long as the rust can be accounted for and accepted as being fixable. And it's got a good vin plate.

As far as restoration cost? More up to you and how far you wanna go. And how much you can do yourself vs have to outsource. Back in '91-92 I spent something like 10 grand for my Muskrat resto, including the car. I did a ton of work myself. Seats, body work, interior restoration, wiring. I outsourced the I6 motor and trans, swapped out a good axle, acquired new wheels and tires, did all the suspension work myself... It was about 75% me and 25% others here and there. And I sold her. Stupid. Today, that'd be gettin' up to about $17-20K in costs total. And I was doing it as cheap as possible, because I didn't have a ton of cash at any given time. Took me 2 years in the backyard too. Worth it, if only for the experience, but also the pride in saying "I did (most) of that!" I hate that I let her go though. Won't be happening with Awesome, I can tell you that. Dunno if I helped or not, but there's my take. I say get it, as long as the rust can be accounted for and accepted as being fixable. And it's got a good vin plate.

But these, and just about every piece of sheet metal for the car, are available. Just how much you wanna spend on it. You might wanna put your eyes on it. The frame and vin plate are the keys to having a '66 Mustang, though, because pretty near *everything* is otherwise available, for fixing or modding. That's where the scary numbers come in. You probably need to put your eyes/hands on it yourself to make your own decision. But 1000-1500 for a straight-enough body and good frame? It sounds like a pretty good basis for a project... Especially if you get it all for $1000. You can probably sell the engine/trans for a lot of that back, I'd guess. Oh, and revisit this thread for my ideas for ya. Not that you'll do it, but... still.

But these, and just about every piece of sheet metal for the car, are available. Just how much you wanna spend on it. You might wanna put your eyes on it. The frame and vin plate are the keys to having a '66 Mustang, though, because pretty near *everything* is otherwise available, for fixing or modding. That's where the scary numbers come in. You probably need to put your eyes/hands on it yourself to make your own decision. But 1000-1500 for a straight-enough body and good frame? It sounds like a pretty good basis for a project... Especially if you get it all for $1000. You can probably sell the engine/trans for a lot of that back, I'd guess. Oh, and revisit this thread for my ideas for ya. Not that you'll do it, but... still.  https://themustangsource.com/forums/...1/#post6971934 Engine/tranny/axle/suspension I leave up to you... provided you get this project.

https://themustangsource.com/forums/...1/#post6971934 Engine/tranny/axle/suspension I leave up to you... provided you get this project.  As far as restoration cost? More up to you and how far you wanna go. And how much you can do yourself vs have to outsource. Back in '91-92 I spent something like 10 grand for my Muskrat resto, including the car. I did a ton of work myself. Seats, body work, interior restoration, wiring. I outsourced the I6 motor and trans, swapped out a good axle, acquired new wheels and tires, did all the suspension work myself... It was about 75% me and 25% others here and there. And I sold her. Stupid. Today, that'd be gettin' up to about $17-20K in costs total. And I was doing it as cheap as possible, because I didn't have a ton of cash at any given time. Took me 2 years in the backyard too. Worth it, if only for the experience, but also the pride in saying "I did (most) of that!" I hate that I let her go though. Won't be happening with Awesome, I can tell you that. Dunno if I helped or not, but there's my take. I say get it, as long as the rust can be accounted for and accepted as being fixable. And it's got a good vin plate.

As far as restoration cost? More up to you and how far you wanna go. And how much you can do yourself vs have to outsource. Back in '91-92 I spent something like 10 grand for my Muskrat resto, including the car. I did a ton of work myself. Seats, body work, interior restoration, wiring. I outsourced the I6 motor and trans, swapped out a good axle, acquired new wheels and tires, did all the suspension work myself... It was about 75% me and 25% others here and there. And I sold her. Stupid. Today, that'd be gettin' up to about $17-20K in costs total. And I was doing it as cheap as possible, because I didn't have a ton of cash at any given time. Took me 2 years in the backyard too. Worth it, if only for the experience, but also the pride in saying "I did (most) of that!" I hate that I let her go though. Won't be happening with Awesome, I can tell you that. Dunno if I helped or not, but there's my take. I say get it, as long as the rust can be accounted for and accepted as being fixable. And it's got a good vin plate.

this is before he patched the cowl

and this is after

and this is after

not sure if you can go through my album with that link but I'll try to post an album link to the mustang pictures I saved that's from his Facebook page. try this link for the album with 37 pictures

http://s1048.photobucket.com/user/ra...ibrary/Mustang

example for grins? as in its relative easy to find/get parts to replace stuff?

he's know about me trying to buy a house with a garage and told me don't sweat it if I don't buy it it will just sit there. as far as laying eyes on it i told him whenever I get free time between workin 40-50hrs a week, trying to finish up my last semester of school and the girlfriend I would come swing by and check it out. so the main things to check are the frame, vin plate and for additional rust?

That's what I figured, if the body is good enough not wrecked and the frame looks god with no rust besides the battery area then that's a pretty good price.

I'm already subscribed to that thread, that blue with white stripes is very nice! hopefully I do get the project! would it be best to just sell the engine and trans right away or to get new seals and gaskets for the engine and try to get that running then later get what engine/trans and all I want.

I am a pretty hands on guy so I can do a lot myself. if not I have my cousin who is a mechanic and my buddies dad who's been rebuilding tractors since he was 13 or so, engine everything.

that's 75/25 sounds like me, I can run wiring and all that myself. yeah that was a bad idea lol, atleast you got some good experience from it.

Yeah you helped me a good bit bud, that's what my plan was once I get serious and have a place to keep it I would go check it out and see if there is any more rust and check frame and all that. thanks for the input!

Last edited by raif281; 3/15/16 at 10:14 PM.

#4

I see the photobucket stuff, and I gotta say, the dude isn't doing you wrong, IMO. He's done some decent work on things, so I think it's a pretty good deal, overall.

I would be concerned most about those cowl vents. They look like they were done... backwards. Water'll flow from the center out, and they look lap jointed on top of the old metal, not the other way around. Perhaps I mis-viewed...

Excepting that, yes, the frame, vin and any other worrisome rust. All you'd be lookin' for. Although I can say that what I see doesn't indicate he's messing with ya in any way.

The doors example is to show that *even* a whole dang door can be bought for these cars. I think the only thing that maybe can't is the actual wing window assembly. Well, and maybe a good T handle upright for the automatic. Been a while since I looked into such things. But even back in '92 just about everything else is doable from a 'just buy it' standpoint... sheet metal, seat covers, carpet, engines, suspension... How big's your wallet is the key. So I figure today, it's gotten even better on stuff.

So I figure today, it's gotten even better on stuff.

I would say that if it were me, I would be *investigating* whether a newer, fuel injected mass air sensor 5.0 engine and AOD (NOT EAOD) (or T-5, if that's your deal) from, oh, 87 and up wouldn't make more sense and sell the engine/trans to a purist. Fuel injection car is way better for storage purposes. Also not cold/hot natured, they just run. Problem with that is retrofitting the engine/computer/linkage into this car, but there's kits for them thar ideas.

Fuel injection car is way better for storage purposes. Also not cold/hot natured, they just run. Problem with that is retrofitting the engine/computer/linkage into this car, but there's kits for them thar ideas.

If you were driving it daily, then I might possibly look into getting a four barrel carb on that engine (which means a new intake, but that should be it) because if you use it, the carb won't gum up and cause ya issues later from sittin' up.

Other than that, I got no more real advice except what I said about the Emberglo Creamery concept I wrote up in that other thread

I'm kinda jelly. Reminds me of good times(tm).

I would be concerned most about those cowl vents. They look like they were done... backwards. Water'll flow from the center out, and they look lap jointed on top of the old metal, not the other way around. Perhaps I mis-viewed...

Excepting that, yes, the frame, vin and any other worrisome rust. All you'd be lookin' for. Although I can say that what I see doesn't indicate he's messing with ya in any way.

The doors example is to show that *even* a whole dang door can be bought for these cars. I think the only thing that maybe can't is the actual wing window assembly. Well, and maybe a good T handle upright for the automatic. Been a while since I looked into such things. But even back in '92 just about everything else is doable from a 'just buy it' standpoint... sheet metal, seat covers, carpet, engines, suspension... How big's your wallet is the key.

So I figure today, it's gotten even better on stuff.

So I figure today, it's gotten even better on stuff.I would say that if it were me, I would be *investigating* whether a newer, fuel injected mass air sensor 5.0 engine and AOD (NOT EAOD) (or T-5, if that's your deal) from, oh, 87 and up wouldn't make more sense and sell the engine/trans to a purist.

Fuel injection car is way better for storage purposes. Also not cold/hot natured, they just run. Problem with that is retrofitting the engine/computer/linkage into this car, but there's kits for them thar ideas.

Fuel injection car is way better for storage purposes. Also not cold/hot natured, they just run. Problem with that is retrofitting the engine/computer/linkage into this car, but there's kits for them thar ideas.

If you were driving it daily, then I might possibly look into getting a four barrel carb on that engine (which means a new intake, but that should be it) because if you use it, the carb won't gum up and cause ya issues later from sittin' up.

Other than that, I got no more real advice except what I said about the Emberglo Creamery concept I wrote up in that other thread

I'm kinda jelly. Reminds me of good times(tm).

Last edited by houtex; 3/15/16 at 10:06 PM.

#5

I see the photobucket stuff, and I gotta say, the dude isn't doing you wrong, IMO. He's done some decent work on things, so I think it's a pretty good deal, overall.

I would be concerned most about those cowl vents. They look like they were done... backwards. Water'll flow from the center out, and they look lap jointed on top of the old metal, not the other way around. Perhaps I mis-viewed...

Excepting that, yes, the frame, vin and any other worrisome rust. All you'd be lookin' for. Although I can say that what I see doesn't indicate he's messing with ya in any way.

The doors example is to show that *even* a whole dang door can be bought for these cars. I think the only thing that maybe can't is the actual wing window assembly. Well, and maybe a good T handle upright for the automatic. Been a while since I looked into such things. But even back in '92 just about everything else is doable from a 'just buy it' standpoint... sheet metal, seat covers, carpet, engines, suspension... How big's your wallet is the key.

So I figure today, it's gotten even better on stuff.

So I figure today, it's gotten even better on stuff. I would say that if it were me, I would be *investigating* whether a newer, fuel injected mass air sensor 5.0 engine and AOD (NOT EAOD) (or T-5, if that's your deal) from, oh, 87 and up wouldn't make more sense and sell the engine/trans to a purist.

Fuel injection car is way better for storage purposes. Also not cold/hot natured, they just run. Problem with that is retrofitting the engine/computer/linkage into this car, but there's kits for them thar ideas.

Fuel injection car is way better for storage purposes. Also not cold/hot natured, they just run. Problem with that is retrofitting the engine/computer/linkage into this car, but there's kits for them thar ideas.

If you were driving it daily, then I might possibly look into getting a four barrel carb on that engine (which means a new intake, but that should be it) because if you use it, the carb won't gum up and cause ya issues later from sittin' up.

Other than that, I got no more real advice except what I said about the Emberglo Creamery concept I wrote up in that other thread

I'm kinda jelly. Reminds me of good times(tm).

Glad to hear you say that I wasn't sure if that's how you properly repair it or if he was doing a half *** job.

Backwards, how so? to me they look oriented like they were from the factory. So you want the water to flow from the outside towards the center? I'm not familiar with this at all. How is it suppose to be done properly can you upload a picture for reference?

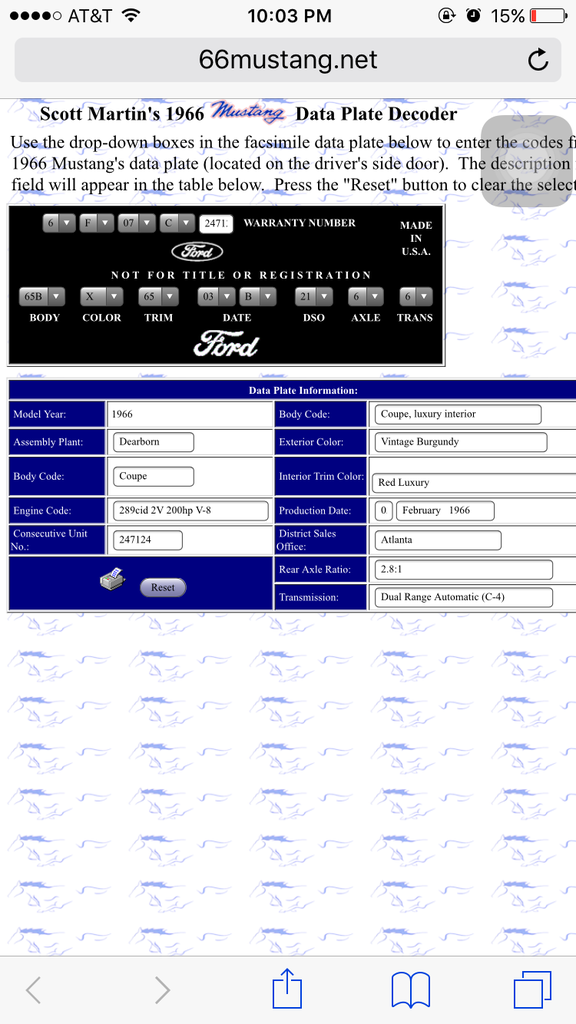

Ok good deal and I hope not! lol like I said he's not a good friend of mine but a friend in the least so I hope he's not screwing me in any way. he was very straight forward about everything. he has the original window sticker that came with it an it had some numbers so I searched the Internet and found this site that decodes it and came up with this

Yeah I got that and that's good to know! well hopefully my wallet will be doubling in size in a few months once I graduate college in May an get a job in my field.

Yeah I was debating keeping the original engine for awhile to save an get another engine/tranny but I'm thinking realistically now. The cars going to be down anyways so might as well do it right the first time! I'm going to try to be a purist as far as interior and body goes but when it comes to the engine/tranny I'll probably get a newer one as it'll be a Sunday driver, taking her to car shows and out to the lakefront when the weathers nice.

lol i did read that and I like the simplistic look of it.

There don't seem to be to many visitors here on this section of the forum. Is there another forum that's more geared towards the 1st gens?

I can't wait to get it and start wrenching on it!

#6

I'm now positive that, unless there's new pictures of it 'done', these are done wrong. I'm sorry to say it, but it's not the end of the world... unless the cowl top is back on...

The deal is this: When the rain water enters the cowl, it'll be in the middle, Where the air vents are on the cowl. Because gravity, the water'll will run towards the sides of the car, around the vents (hence the 'top hats' on those) and inside and down the fenders, then drip out to the ground. As will leaves and whatnot, the reason for the rusting of the vents in there. The detritus will get trapped, and moisture follows, then rust holes. Don't park under trees.

So... using that basic water flow... the panels that replaced the rusted out vents are welded on backwards, because they are sitting on TOP of the remaining old cowl 'floor'. Which would trap water when it was welded/seam sealed. Which is what you absolutely don't want. And you also don't want them to be done the other way, UNDER the old panel.

Because in either case, you'll HAVE to use seam sealer there, and it would be a bad BAD move. Seam sealer will trap the water the same as a weld joint that's not butt joined and smoothed.

Optimal would be to have them old and new panels butt joined, welded, and ground smooth, then POR15 primered so that there's no chance whatsoever of water flow interruption and trapping of the water so there'll be rust. You also won't need seam sealer there because it's a smooth, uniform surface, not lapped joined.

Lap joined means what I said above: One panel's overLAPping the other. Hence, lap join. Put one panel on top, then spot weld? Sorry, that's probably gonna rust a whole lot faster than not. I wouldn't do it there at all, purely for the water flow.

It's harder to do, sure, but you want it done right, that's how it's done right. And it can be fixed, just need to do it.

But that's me, Mr. OCD... who used Por 15 putty to fix the holes in his 'top hats', then stuck plastic repair top hat kits in them big holes, and tested it with a hose, no leaks, because I couldn't hack the car up and fix it at the time.

I guarantee you that would not happen that way if I did it again. It would be done like I described.

Ok, that's it. All I'm tellin' ya. Get out there and make me my Emberglo Creamery Mustang happen.

The deal is this: When the rain water enters the cowl, it'll be in the middle, Where the air vents are on the cowl. Because gravity, the water'll will run towards the sides of the car, around the vents (hence the 'top hats' on those) and inside and down the fenders, then drip out to the ground. As will leaves and whatnot, the reason for the rusting of the vents in there. The detritus will get trapped, and moisture follows, then rust holes. Don't park under trees.

So... using that basic water flow... the panels that replaced the rusted out vents are welded on backwards, because they are sitting on TOP of the remaining old cowl 'floor'. Which would trap water when it was welded/seam sealed. Which is what you absolutely don't want. And you also don't want them to be done the other way, UNDER the old panel.

Because in either case, you'll HAVE to use seam sealer there, and it would be a bad BAD move. Seam sealer will trap the water the same as a weld joint that's not butt joined and smoothed.

Optimal would be to have them old and new panels butt joined, welded, and ground smooth, then POR15 primered so that there's no chance whatsoever of water flow interruption and trapping of the water so there'll be rust. You also won't need seam sealer there because it's a smooth, uniform surface, not lapped joined.

Lap joined means what I said above: One panel's overLAPping the other. Hence, lap join. Put one panel on top, then spot weld? Sorry, that's probably gonna rust a whole lot faster than not. I wouldn't do it there at all, purely for the water flow.

It's harder to do, sure, but you want it done right, that's how it's done right. And it can be fixed, just need to do it.

But that's me, Mr. OCD... who used Por 15 putty to fix the holes in his 'top hats', then stuck plastic repair top hat kits in them big holes, and tested it with a hose, no leaks, because I couldn't hack the car up and fix it at the time.

I guarantee you that would not happen that way if I did it again. It would be done like I described.

Ok, that's it. All I'm tellin' ya. Get out there and make me my Emberglo Creamery Mustang happen.

#7

I'm now positive that, unless there's new pictures of it 'done', these are done wrong. I'm sorry to say it, but it's not the end of the world... unless the cowl top is back on...

The deal is this: When the rain water enters the cowl, it'll be in the middle, Where the air vents are on the cowl. Because gravity, the water'll will run towards the sides of the car, around the vents (hence the 'top hats' on those) and inside and down the fenders, then drip out to the ground. As will leaves and whatnot, the reason for the rusting of the vents in there. The detritus will get trapped, and moisture follows, then rust holes. Don't park under trees.

So... using that basic water flow... the panels that replaced the rusted out vents are welded on backwards, because they are sitting on TOP of the remaining old cowl 'floor'. Which would trap water when it was welded/seam sealed. Which is what you absolutely don't want. And you also don't want them to be done the other way, UNDER the old panel.

Because in either case, you'll HAVE to use seam sealer there, and it would be a bad BAD move. Seam sealer will trap the water the same as a weld joint that's not butt joined and smoothed.

Optimal would be to have them old and new panels butt joined, welded, and ground smooth, then POR15 primered so that there's no chance whatsoever of water flow interruption and trapping of the water so there'll be rust. You also won't need seam sealer there because it's a smooth, uniform surface, not lapped joined.

Lap joined means what I said above: One panel's overLAPping the other. Hence, lap join. Put one panel on top, then spot weld? Sorry, that's probably gonna rust a whole lot faster than not. I wouldn't do it there at all, purely for the water flow.

It's harder to do, sure, but you want it done right, that's how it's done right. And it can be fixed, just need to do it.

But that's me, Mr. OCD... who used Por 15 putty to fix the holes in his 'top hats', then stuck plastic repair top hat kits in them big holes, and tested it with a hose, no leaks, because I couldn't hack the car up and fix it at the time.

I guarantee you that would not happen that way if I did it again. It would be done like I described.

Ok, that's it. All I'm tellin' ya. Get out there and make me my Emberglo Creamery Mustang happen.

The deal is this: When the rain water enters the cowl, it'll be in the middle, Where the air vents are on the cowl. Because gravity, the water'll will run towards the sides of the car, around the vents (hence the 'top hats' on those) and inside and down the fenders, then drip out to the ground. As will leaves and whatnot, the reason for the rusting of the vents in there. The detritus will get trapped, and moisture follows, then rust holes. Don't park under trees.

So... using that basic water flow... the panels that replaced the rusted out vents are welded on backwards, because they are sitting on TOP of the remaining old cowl 'floor'. Which would trap water when it was welded/seam sealed. Which is what you absolutely don't want. And you also don't want them to be done the other way, UNDER the old panel.

Because in either case, you'll HAVE to use seam sealer there, and it would be a bad BAD move. Seam sealer will trap the water the same as a weld joint that's not butt joined and smoothed.

Optimal would be to have them old and new panels butt joined, welded, and ground smooth, then POR15 primered so that there's no chance whatsoever of water flow interruption and trapping of the water so there'll be rust. You also won't need seam sealer there because it's a smooth, uniform surface, not lapped joined.

Lap joined means what I said above: One panel's overLAPping the other. Hence, lap join. Put one panel on top, then spot weld? Sorry, that's probably gonna rust a whole lot faster than not. I wouldn't do it there at all, purely for the water flow.

It's harder to do, sure, but you want it done right, that's how it's done right. And it can be fixed, just need to do it.

But that's me, Mr. OCD... who used Por 15 putty to fix the holes in his 'top hats', then stuck plastic repair top hat kits in them big holes, and tested it with a hose, no leaks, because I couldn't hack the car up and fix it at the time.

I guarantee you that would not happen that way if I did it again. It would be done like I described.

Ok, that's it. All I'm tellin' ya. Get out there and make me my Emberglo Creamery Mustang happen.

**** and no idea if the cowl top is on or not. I'm going to have to talk to him and see or check it out when I go look at it. ahh ok I understand now it passes the top hats up an goes into the fender, I was confused and thought it went down the top hat somehow to drain but that's your vent. well once I get it repaired and running it will stay under a carport or in the garage. We have Cyprus trees in front the house we live in now an I absolutely hate them they get everywhere!

I got it, so I would need to redo it and make them smooth so water flows evenly across them an doesn't get trapped on the lip of the overlap. haha that's why this will be sitting in a garage at the new house so I can take my time and go through everything make sure it's good an redo what needs to be done.

well see about the emberglo creamery mustang, I do like the simplicity of it. first we need to get a house with a garage then I can go get it an start on her.

Thread

Thread Starter

Forum

Replies

Last Post