Ford Uses Video Game Tech to Make Workers Safer

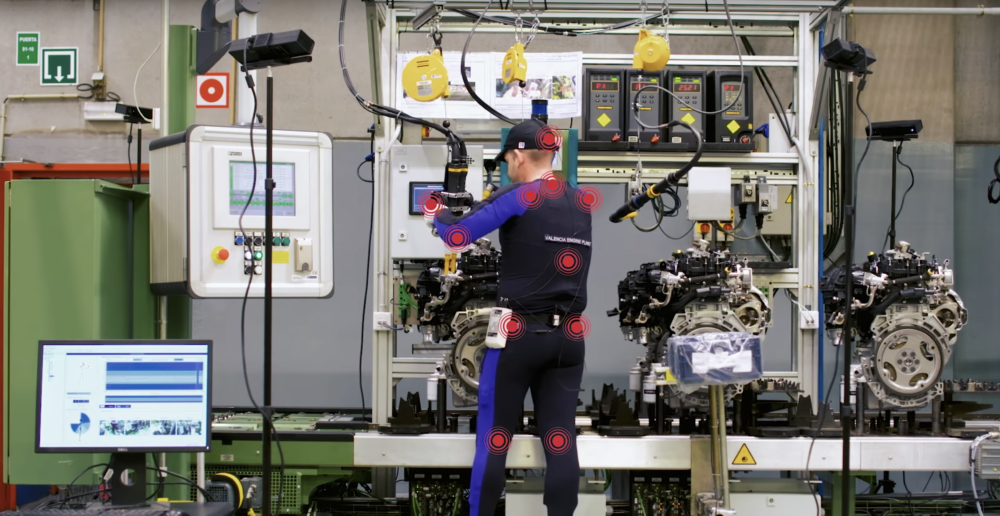

Safety program uses special suits with 15 light sensors & nearby Microsoft Kinect motion-tracking cameras to record the way they move.

If you’ve ever played any sports video game, you may know that game developers often put pro athletes in skin-tight suits with sensors all over them. They have them move, then a 3D camera creates a digital version of that player. Well, now Ford is having workers in Valencia, Spain do the same. And it’s all in the name of improving worker ergonomics.

The pilot program, at Ford’s Valencia Engine Assembly Plant in Spain, involves 70 workers in 21 different departments. According to Ford, player motion technology usually records how athletes sprint or turn, enabling sport coaches or game developers to unlock the potential of sport stars in the real world or on screen. Ford is using it to design less physically stressful workstations for enhanced manufacturing quality.

“It’s been proven on the sports field that with motion tracking technology, tiny adjustments to the way you move can have a huge benefit,” says plant manager Javier Gisbert. “For our employees, changes made to work areas using similar technology can ultimately ensure that, even on a long day, they are able to work comfortably.”

Ford & Microsoft

Workers on the program are wearing a special suit with 15 light sensors in it. Four nearby Microsoft Kinect cameras, famously packaged with the Xbox One, have motion-tracking capabilities and take in the employee’s movements and record the way they move while they work. From there, ergonomists work with the employees to make changes that make their workstations safer and more comfortable.

Ford’s interest in reducing worker injuries has been around for years. And this latest move is a high-tech solution that could yield real results. The company is eager to see how this improves conditions at the plant. If successful, it would continue at different European plants. After that, it could come to America. Could it come to the Mustang’s Flat Rock, Michigan plant eventually? Only time will tell.

Not everybody loves the idea of someone studying you at work. But this sounds like a worthwhile program. If we could sign up for a program that would make us healthier, safer, and more efficient at work, we probably would.