Increased Throttle Response!!!

#1

Increased Throttle Response!!!

This was written and performed by "tube" on the other forum:

"Anyone ever notice that really anoying 1/2" or so of dead space in the gas pedal before the engine actually begins to rev?

My last car was a Subaru WRX with a cable throttle, I LOVED it, so responsive, so crisp.

Then I get my Mustang. The gas pedal is unresponsive, has load of dead space, and is a drivers nightmare.

Everyone always claims a tune helps their throttle response, so I purchased a Brenspeed C&L intake + SCT flasher combo. Unfortunately, 9 days after ordering it, no tracking # or item...

So today I'm at work thinking how I can mechanically remove that "dead space" in the gas pedal.

In my head, I picture the gas pedal module as being a carbon potentiometer, with a brush that is connected to the gas pedal, and moves, changing the resistance of the potentiometer, and thusly telling the ECU to open the throttle body.

Thinking some more, I decide to get my hands dirty.

I go in my footwell and look at my gas pedal. Simple enough, a black box with a plastic pedal coming out of it, three 10mm nuts, and 5 TORX screws holding a cover on the side, with an electrical connector and harness plugged into it.

I remove the three 10mm nuts, unclip the harness, and remove the entire pedal assembly.

Holding it my hand, I look at the cover, and take my T15 TORX driver and remove the cover. I pop the cover off, and VOILA to my assumption, a small circuit board, with a wedge shaped carbon film set of tracks, I think there are 6 to be exact.

I look at the inside of the gas pedal, and I see 6 little metal tabs, with about ten very fine metal wires, spot welded to the metal tabs, and bent up in a _/ shape to make contact with the carbon film on the circuit board.

I can clearly see a shiny track in the carbon on the circuit board where the metal brushes were rubbing against.

To my amazement, the track was starting about 2mm before the brush actually even TOUCHED the sensitive carbon part!!!

I take a pair of fine jewlers pliers, and bend each metal brush and tab just a few millimeters so that they will make perfect contact right on the edge of the carbon film.

I screw the cover back on, screw the gas pedal back onto the firewall and plug in the harness.

Start the engine, wait for the idle to drop. Perfect, idling around 700. I tap the gas pedal (with the tip of my TOE!)

and......

OH MY GOSH THE THROTTLE IS SO RESPONSIVE.

THE DEADSPACE IS GONE! ITS PERFECT!

It's amazing how such a small modification makes a HUGE difference in driveability and response.

If anyone wants pictures on how to do this, let me know.

Please digg my story!

Digg - Improving Drive By Wire Throttle Response Though Mechanical Means.

Step 1:

Remove Three 10mm nuts holding gas pedal to firewall:

Step 2:

Slide back red lock tab on connector:

Step 3:

Use flat head screw driver to press tab down inside of connector, and pull connector away from gas pedal assembly:

Step 4:

Take pedal assembly over to your workbench. Remove five TORX T-15 screws on electrical cover.

Step 5:

Remove electronic cover: Notice how the circuit board says REV 1.0? That means they haven't revised this gas pedal assembly since they first used it back in 2005!!! (My car is a 2008!)

http://i6.tinypic.com/67grd47.jpg

Notice the circuit board with the wedge shaped carbon tracks. Notice the shiny marks on the tracks. See how they start slightly before the end of the gold track? That is your deadspace! Any movement before the very edge of the gold track will not be registered by the ECU!!!

THE ONLY WAY to fix this is mechanical adjustment. NO amount of tuning can remove this deadspace, it's simply impossbile!

Step 6:

Look at the pedal assembly. Notice the metal tabs and fine wire brushes? These are what we want to modify.

Very carefully, bend the brushes up so that they don't have such a steep angular bend in their tips. I have already done this in these photos, so it's not apparent how sharp the bend in the wires were prior to me modifying them. They are like this _/ and you want them to be straighter so that they move closer to the edge of the brass/carbon track.

Using some fine pliers, carefully bend the tips of the wires. These are VERY fine wires, be very careful.

Now bend the entire metal tabs up very slightly to compensate for the change in angle at the tips of the wires.

http://i9.tinypic.com/4tanz8m.jpg

More pictures of the wires:

Another shot of the circuit board:

Notice that by bending the wires, we are moving them closer to the edge of the carbon/gold seam. This removes the dead space.

Step 7:

Put the cover back onto the pedal assembly. NOTE: There is a rubber gasket that goes in the slot. MAKE SURE not to lose it, or crush it, this could cause your vehicle to accelerate uncontrolably! Screw the 5 TORX screws back in VERY CAREFULLY do not distort the cover, or you may bend the wires and cause bad ju ju.

Re-install the pedal, and enjoy your new dead space free throttle!

I am not responsible if you ruin your 50$ gas pedal assembly by breaking off the fine wires, or over bending them."

"Anyone ever notice that really anoying 1/2" or so of dead space in the gas pedal before the engine actually begins to rev?

My last car was a Subaru WRX with a cable throttle, I LOVED it, so responsive, so crisp.

Then I get my Mustang. The gas pedal is unresponsive, has load of dead space, and is a drivers nightmare.

Everyone always claims a tune helps their throttle response, so I purchased a Brenspeed C&L intake + SCT flasher combo. Unfortunately, 9 days after ordering it, no tracking # or item...

So today I'm at work thinking how I can mechanically remove that "dead space" in the gas pedal.

In my head, I picture the gas pedal module as being a carbon potentiometer, with a brush that is connected to the gas pedal, and moves, changing the resistance of the potentiometer, and thusly telling the ECU to open the throttle body.

Thinking some more, I decide to get my hands dirty.

I go in my footwell and look at my gas pedal. Simple enough, a black box with a plastic pedal coming out of it, three 10mm nuts, and 5 TORX screws holding a cover on the side, with an electrical connector and harness plugged into it.

I remove the three 10mm nuts, unclip the harness, and remove the entire pedal assembly.

Holding it my hand, I look at the cover, and take my T15 TORX driver and remove the cover. I pop the cover off, and VOILA to my assumption, a small circuit board, with a wedge shaped carbon film set of tracks, I think there are 6 to be exact.

I look at the inside of the gas pedal, and I see 6 little metal tabs, with about ten very fine metal wires, spot welded to the metal tabs, and bent up in a _/ shape to make contact with the carbon film on the circuit board.

I can clearly see a shiny track in the carbon on the circuit board where the metal brushes were rubbing against.

To my amazement, the track was starting about 2mm before the brush actually even TOUCHED the sensitive carbon part!!!

I take a pair of fine jewlers pliers, and bend each metal brush and tab just a few millimeters so that they will make perfect contact right on the edge of the carbon film.

I screw the cover back on, screw the gas pedal back onto the firewall and plug in the harness.

Start the engine, wait for the idle to drop. Perfect, idling around 700. I tap the gas pedal (with the tip of my TOE!)

and......

OH MY GOSH THE THROTTLE IS SO RESPONSIVE.

THE DEADSPACE IS GONE! ITS PERFECT!

It's amazing how such a small modification makes a HUGE difference in driveability and response.

If anyone wants pictures on how to do this, let me know.

Please digg my story!

Digg - Improving Drive By Wire Throttle Response Though Mechanical Means.

Step 1:

Remove Three 10mm nuts holding gas pedal to firewall:

Step 2:

Slide back red lock tab on connector:

Step 3:

Use flat head screw driver to press tab down inside of connector, and pull connector away from gas pedal assembly:

Step 4:

Take pedal assembly over to your workbench. Remove five TORX T-15 screws on electrical cover.

Step 5:

Remove electronic cover: Notice how the circuit board says REV 1.0? That means they haven't revised this gas pedal assembly since they first used it back in 2005!!! (My car is a 2008!)

http://i6.tinypic.com/67grd47.jpg

Notice the circuit board with the wedge shaped carbon tracks. Notice the shiny marks on the tracks. See how they start slightly before the end of the gold track? That is your deadspace! Any movement before the very edge of the gold track will not be registered by the ECU!!!

THE ONLY WAY to fix this is mechanical adjustment. NO amount of tuning can remove this deadspace, it's simply impossbile!

Step 6:

Look at the pedal assembly. Notice the metal tabs and fine wire brushes? These are what we want to modify.

Very carefully, bend the brushes up so that they don't have such a steep angular bend in their tips. I have already done this in these photos, so it's not apparent how sharp the bend in the wires were prior to me modifying them. They are like this _/ and you want them to be straighter so that they move closer to the edge of the brass/carbon track.

Using some fine pliers, carefully bend the tips of the wires. These are VERY fine wires, be very careful.

Now bend the entire metal tabs up very slightly to compensate for the change in angle at the tips of the wires.

http://i9.tinypic.com/4tanz8m.jpg

More pictures of the wires:

Another shot of the circuit board:

Notice that by bending the wires, we are moving them closer to the edge of the carbon/gold seam. This removes the dead space.

Step 7:

Put the cover back onto the pedal assembly. NOTE: There is a rubber gasket that goes in the slot. MAKE SURE not to lose it, or crush it, this could cause your vehicle to accelerate uncontrolably! Screw the 5 TORX screws back in VERY CAREFULLY do not distort the cover, or you may bend the wires and cause bad ju ju.

Re-install the pedal, and enjoy your new dead space free throttle!

I am not responsible if you ruin your 50$ gas pedal assembly by breaking off the fine wires, or over bending them."

#2

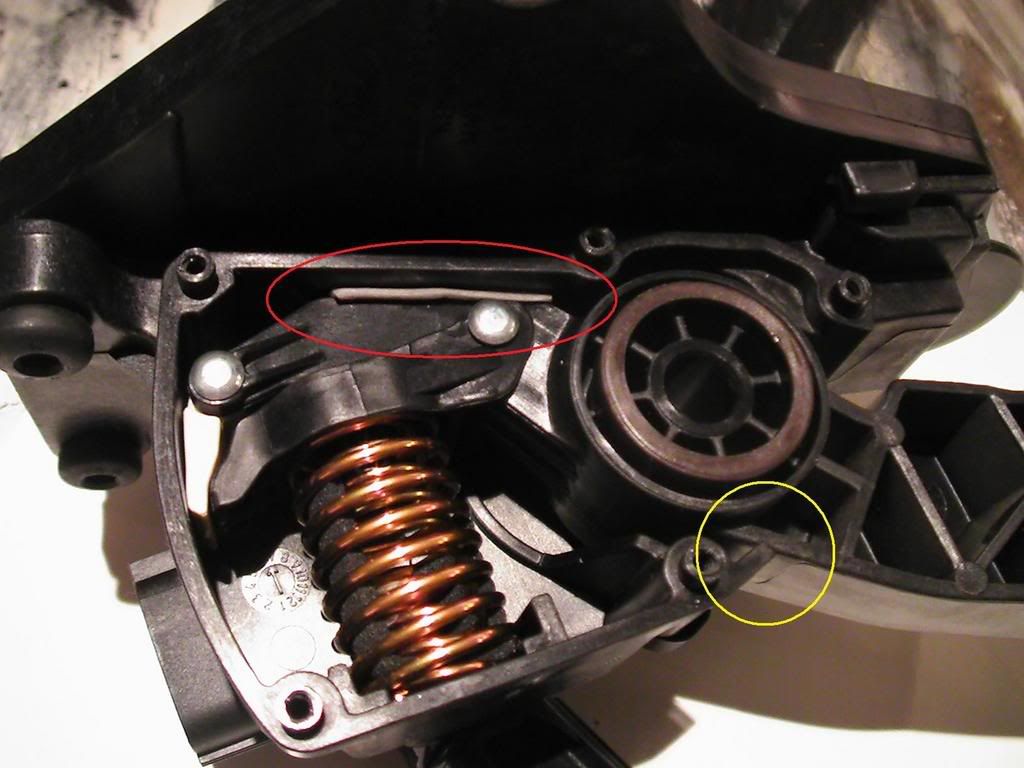

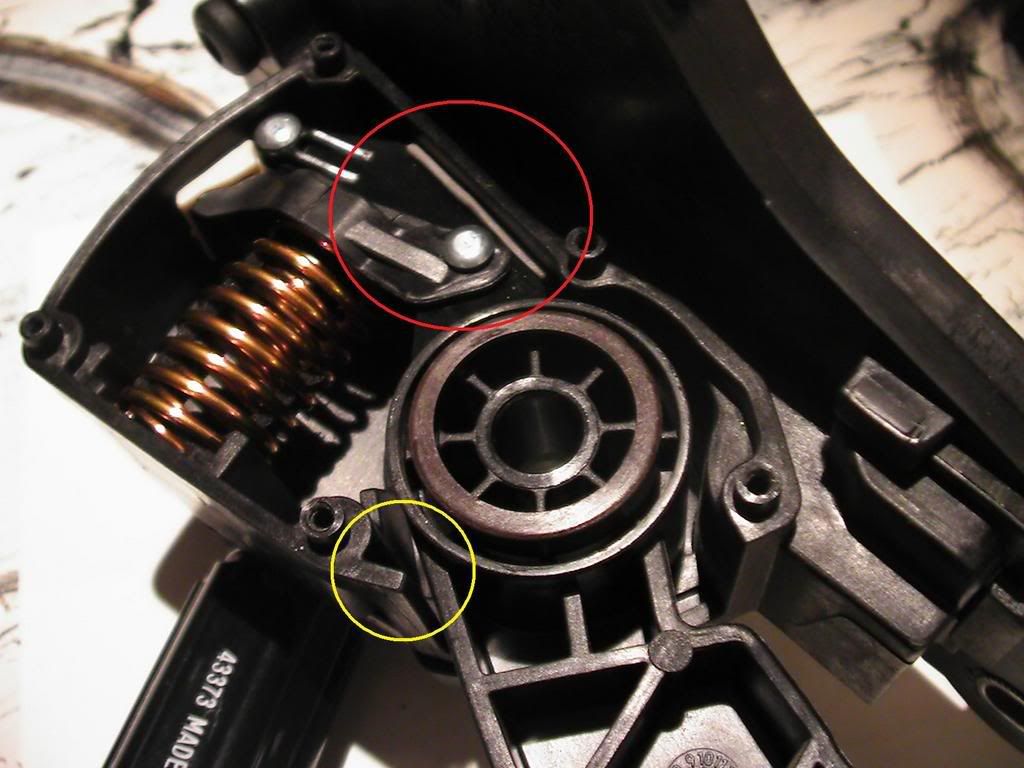

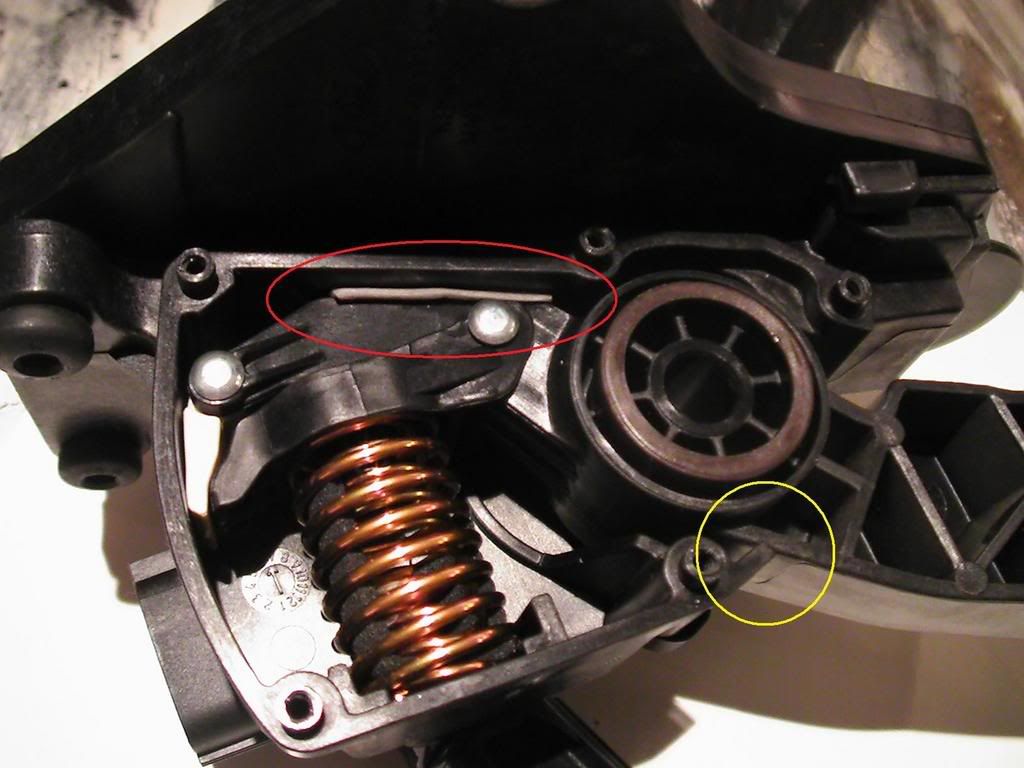

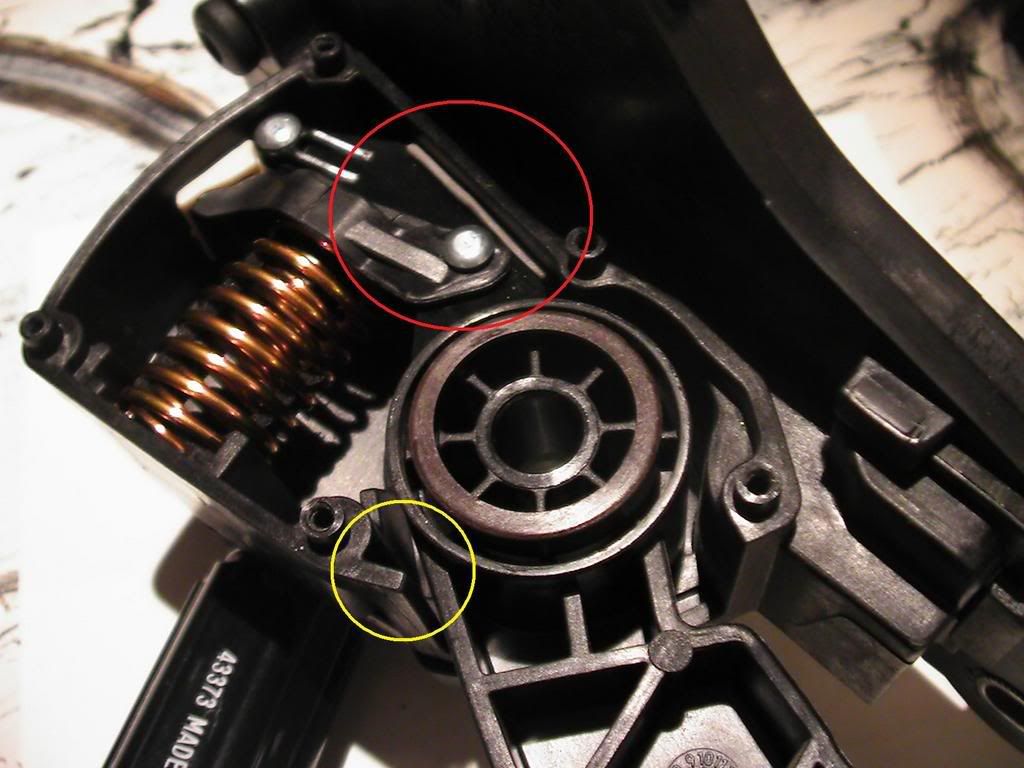

Okay. I took mine off and here's the pedal.... open the RIGHT cover... the brushes are not on this side. tbird proposes installing the tape in shaft indicated by YELLOW CIRCLE... no no, it's going to be wedged in there and will not do hold more than day or two... the tape I have is indicated with RED CIRCLE. This stops the pedal (brushes) going too far (off the strip on the LEFT side cover).

Hope this helps. Need more beer...

__________________

Miikka

2007 GT/CS - Saleen S/C - Lotsa mods - Tuned by VMP

Last edited by mvon919 : 09-03-2007 at 12:42 AM.

mvon919View Public ProfileSend a private message to mvon919Find More Posts by mvon919Add mvon919 to Your Buddy List

09-03-2007, 01:02 AM #20 (permalink) mvon919 vbmenu_register("postmenu_963059", true);

09-03-2007, 01:02 AM #20 (permalink) mvon919 vbmenu_register("postmenu_963059", true);

Senior Member

Join Date: Nov 2006

Location: Front Range, CO

Posts: 572

Re: MODIFYING The Gas Pedal Module [better response?]

Re: MODIFYING The Gas Pedal Module [better response?]

Okay... got more beer. I took the pedal off and noticed the spring is pressing hard against the tape (YOU CAN imagine how hard it'll press in the yellow circle area)... well, I cut a piece of hard gray plastic and sticked it into the double sided tape. So, tomorrow morning, I'll go install the pedal, calibrate the throttle (key ON, step slowly on the pedal until WOT and release quikly, key OFF), start the car and hope everything works well.

Check pics.

Hope this helps. Need more beer...

__________________

Miikka

2007 GT/CS - Saleen S/C - Lotsa mods - Tuned by VMP

Last edited by mvon919 : 09-03-2007 at 12:42 AM.

mvon919View Public ProfileSend a private message to mvon919Find More Posts by mvon919Add mvon919 to Your Buddy List

Senior Member

Join Date: Nov 2006

Location: Front Range, CO

Posts: 572

Okay... got more beer. I took the pedal off and noticed the spring is pressing hard against the tape (YOU CAN imagine how hard it'll press in the yellow circle area)... well, I cut a piece of hard gray plastic and sticked it into the double sided tape. So, tomorrow morning, I'll go install the pedal, calibrate the throttle (key ON, step slowly on the pedal until WOT and release quikly, key OFF), start the car and hope everything works well.

Check pics.

#3

I Am Just Copying And Pasting From Modularfords.com This Is Not My Information... Everything Stated Above Is Copied And Pasted

#4

#5

HERES ANOTHER WAY

Ok boys, stop the presses. Ive figured out a third way to solve this. You dont have to risk breaking chit bending wires and you dont have to **** around with tape or epoxy.

I was going to do the "Tube" mod. I took it apart as described and said, "Eff this, Im not going break this, lets try the tape". However, while it was apart, I worked the pedal a bit to see exactly what was going on and why the tape works. As I was replacing the brush cover I noticed theres play in how it fits on the body. Well, all I did was push the brush cover up against the lower edge of the gasket body. Look at Tubes pic below. After placing the brush cover on the body, using the same orientation as the pic I pushed up on the cover and screwed in place. You have to be gentle but hold firm as the screw will want to go back to their original threads as well as push against the cover.

Why does THIS work? Well, everyone keeps mentioning tolerances. Well, where do they come from? They come from the slop in the brush cover as its screwed into place on the body. When you look at the cover youll see the the holes are elongated. So, simply holding it in place against the body and the bottom of the elongation solves this problem, No tampering inside, no tape to **** with or wear out and no evidence to cause a warranty void. Now my throttle responds just like it should, like my old 02 GT or even my Torino. Granted, I still need and want a tune to affect the linearity, response and "volume" of the throttle, but at least now when I blip between downshifts it WILL respond. I cant wait to drive it now. Will shortly once I get my crap cleaned up. Ill report back.

Ok boys, stop the presses. Ive figured out a third way to solve this. You dont have to risk breaking chit bending wires and you dont have to **** around with tape or epoxy.

I was going to do the "Tube" mod. I took it apart as described and said, "Eff this, Im not going break this, lets try the tape". However, while it was apart, I worked the pedal a bit to see exactly what was going on and why the tape works. As I was replacing the brush cover I noticed theres play in how it fits on the body. Well, all I did was push the brush cover up against the lower edge of the gasket body. Look at Tubes pic below. After placing the brush cover on the body, using the same orientation as the pic I pushed up on the cover and screwed in place. You have to be gentle but hold firm as the screw will want to go back to their original threads as well as push against the cover.

Why does THIS work? Well, everyone keeps mentioning tolerances. Well, where do they come from? They come from the slop in the brush cover as its screwed into place on the body. When you look at the cover youll see the the holes are elongated. So, simply holding it in place against the body and the bottom of the elongation solves this problem, No tampering inside, no tape to **** with or wear out and no evidence to cause a warranty void. Now my throttle responds just like it should, like my old 02 GT or even my Torino. Granted, I still need and want a tune to affect the linearity, response and "volume" of the throttle, but at least now when I blip between downshifts it WILL respond. I cant wait to drive it now. Will shortly once I get my crap cleaned up. Ill report back.

#7

unn thanks??

#9

so jerbear, hows the drive now??? any differance?

#10

I havent done this yet. EVERYTHING ABOVE WAS COPIED AND PASTED FROM ANOTHER FORUM.. as stated above

#11

The small lag that I had went away after I installed the tunes from Brenspeed.

#12

A tune cant get rid of Dead space. But all production mustangs dont have this problem. If you can sit at idle and pust the peddle in stlightly and the RPMs dont go up than you have dead space. Mine 1/4 inch dead space

#13

Mine has no dead space. They must have built yours on a fri. or a mon.

#14

they must have built yours on my butt

#15

It is large enough for an entire assembly plant.

#16

There a bunch of dead space between Jarrods ears...

#17

yeah just like in your pants paul....sorry got my info from the zippers guy ...I mean girl (wink wink) you went home with last night