3D Printing Could Change Mustang’s Future

Ford Looks to Build on Innovative 3D-Printing Process for Vehicle Development

Could future production Mustangs be built by a 3D-printing process?

Well, if the technology advancements being made by Ford Motor Co. continue to progress, it certainly doesn’t seem that far-fetched.

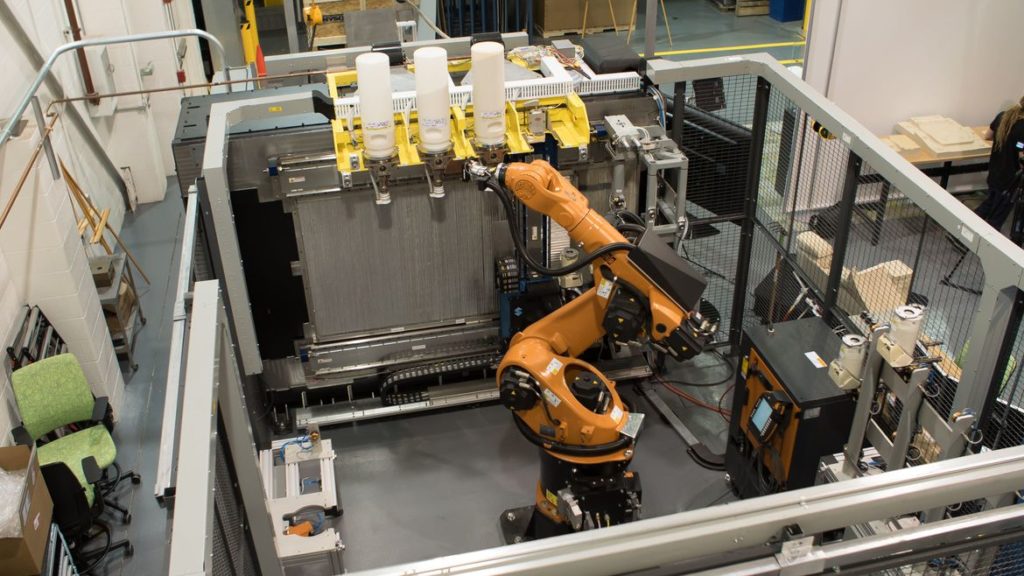

The Detroit carmaker has been aggressively exploring how they can improve the high-tech development and build process. One way includes 3D printing for actual vehicle parts, according to a CNET report. Ford has even constructed a new “room-sized” printer for the process: the Stratasys Infinite Build 3D printer.

CHECK OUT: What Forum Members Are Saying About the Mustang’s Three-Dimensional Future

At the core of Ford’s strategy is a new innovative 3D-printing process capable of producing much larger objects than the conventional 3D process. The new process, dubbed as “Stratasys,” is also more structurally sound, due in large part to the fact that it layers in support structures for the objects it creates. It builds things horizontally instead of vertically, so there are no space constraints or size constraints with what they can build.

In addition, the process uses proprietary micro-pellet powder, instead of the filament-like material used by most commercial printers. When building an actual part, the thermoplastic micro-pellet powder is fed into a screw-drive and heated and transformed into a part. The entire process can then be continued for hours and hours, thanks to a robotic arm capable of refilling the canisters used to print the parts.

At this point, Ford is taking a more test, wait, and see approach in terms of the potential long-term benefits of the Stratasys Infinite Build 3D Printer. But it certainly seems clear that the process, which was once used primarily for preliminary development of vehicles, could soon become a more dominate part of actual cars on the road.